What new machining technologies are applied to a crankshaft production line with an annual capacity of 200,000 units?

How does the high-speed crankshaft machining production line do it? Its distinctive feature is the adoption of new crankshaft machining technologies that have emerged in recent years, such as punching quality center holes, high-speed external milling, and the use of CNC crankshaft grinders to simplify the process, as well as the extensive use of CNC control technology and robots to form an automated production line, which shortens the machining time of a single piece of product and thus directly improves the production efficiency.

Crankshaft machining process

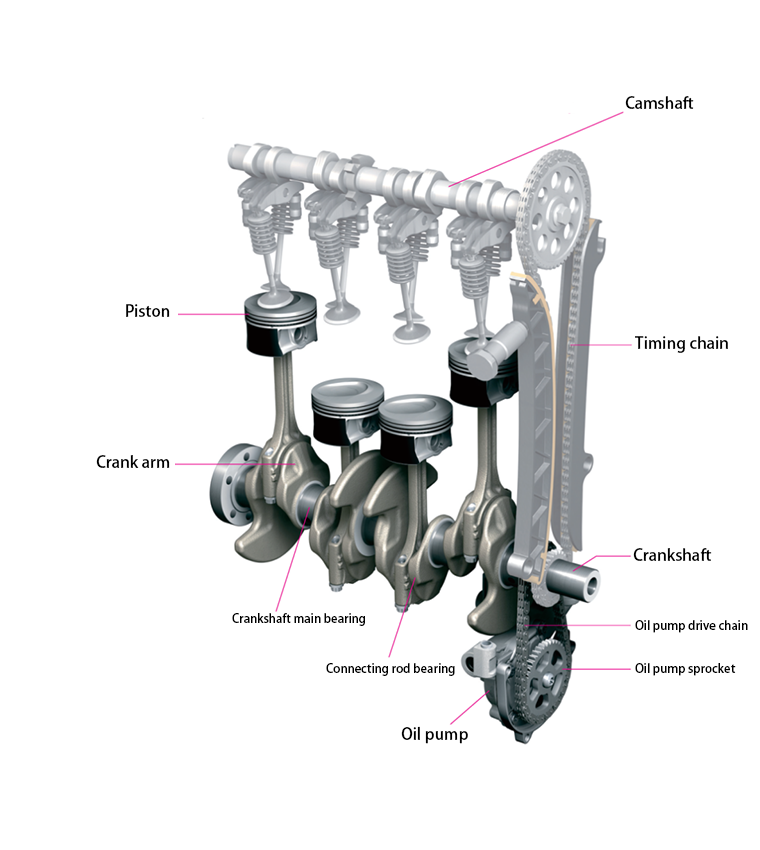

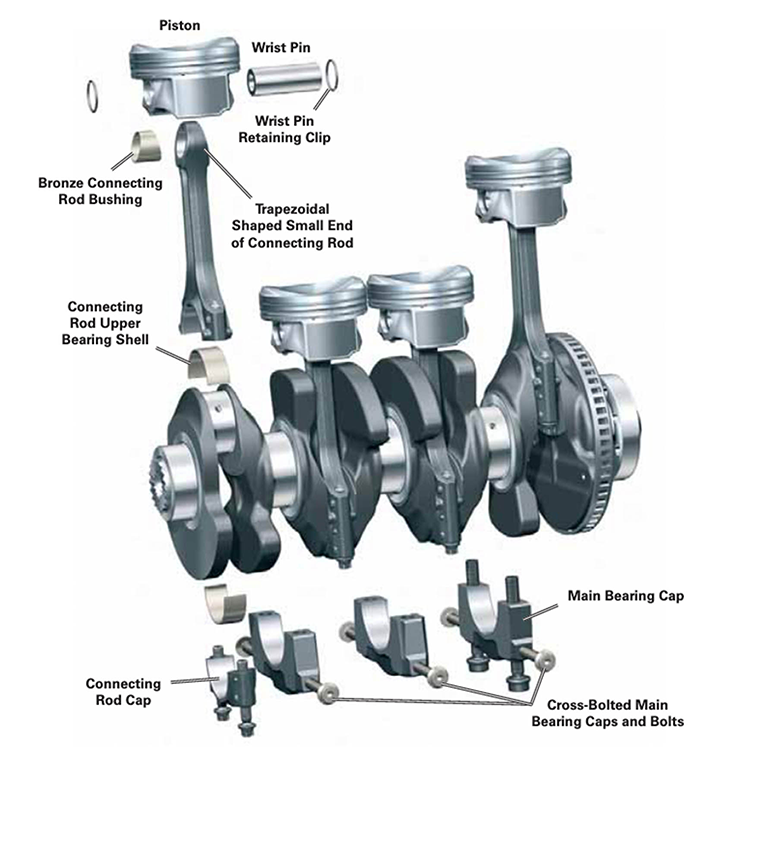

Typical process flow of crankshaft machining for turbocharged engines of passenger cars: dynamic balancing, drilling the center of mass hole → turning the 5th main journal → turning the flange → rough machining the main journal, connecting rod journal and shaft shoulder → drilling the oil passage hole and chamfering → rough grinding the main journal, connecting rod journal journal, side wall and countersinking groove → cleaning, blow-drying → rounded rolling → fine turning, rolling the thrust surface + fine turning the small end → fine turning the flange end and groove → fine grinding the main journal, connecting rod journal, Small end → machining of threaded holes at both ends, pin holes and reaming of center holes of flange end → fine grinding of crankshaft flange end → crankshaft dynamic balancing and de-weighting → abrasive belt polishing of main shaft neck, connecting rod neck and flange outer neck → automatic checking and marking → final cleaning of crankshaft.

Application of advanced technology

The positioning reference in the crankshaft machining process is the center hole, which can be divided into the geometric center hole and the quality center hole according to its machining position. The geometric center of the crankshaft’s main bearing journal is found out by using the V-shaped block or other means, and the center hole machined on this center is called the geometric center hole. The center of mass of the crankshaft is measured using special test equipment, and the center hole machined on this center is called the center hole of mass. When the geometric center hole is used for subsequent turning and grinding, the centrifugal force generated by the rotation of the workpiece will affect the quality of processing, and the remaining dynamic imbalance after machining is large, and it is necessary to repeatedly measure and de-emphasize the weight in the dynamic balancing process in order to meet the technical requirements, which is inefficient, affects the production beat, and causes an increase in the rate of semi-finished product rejects and the loss of positioning elements. Adopting the center of mass hole can solve such problems and improve the cycle beat.

High-speed external milling roughing crankshaft main journal, connecting rod journal and shoulder, than CNC turning, CNC internal milling, car – car pulling high productivity and stable quality. For example, CNC turning – turning and pulling process requires two processes to machine connecting rod journals, while CNC high-speed external milling can be completed in just one process. The significant features of high-speed external milling roughing crankshaft are: cutting speed up to 350m/min, short cutting time, short cycle time of the process, lower cutting force, low temperature rise of the workpiece, high tool life, fewer tool changes, and higher machining accuracy, Flexibility is better, is the development direction of crankshaft main journal and connecting rod journal roughing.

Rough grinding of main shaft journals, connecting rod journal journals, side walls and countersinking grooves. CNC crankshaft grinding machine can grind all crankshaft main journal and connecting rod journal in one clamping. This kind of grinding machine is generally equipped with double grinding wheel headstock, which can meet the requirements of multi-species, cost, high precision and mass production, and apply the servo-linkage control technology of workpiece rotary and grinding wheel feed to complete all journals grinding without changing the crankshaft rotary center at one time clamping, including the follower tracking grinding of the connecting rod journal; adopting the static-pressure main shaft, static-pressure guideway, static-pressure feed screw (wheel headstock) and linear grating closed-loop control system, the grinding journal roundness can be achieved. The use of hydrostatic spindle, hydrostatic guideway, hydrostatic feed screw (grinding wheel headstock) and linear grating closed-loop control system ensures high accuracy of grinding journal roundness and high grinding efficiency.

DANOBAT NA750 crankshaft thrust face finish turning machine is equipped with an automatic inspection device. After the part is clamped, the measuring head automatically detects the width of the thrust face, determines its centerline, takes it as the machining reference and automatically compensates for it according to the machining of the previous crankshaft, thus realizing the finish turning of the two sides of the thrust face with the centerline as the machining reference and with equal allowances, and then the width of the thrust face is automatically detected after the completion of the turning. After turning, the width of the thrust face is automatically detected, and the processing of the small end and groove is completed at the same time. After the turning is completed, the turning tool is returned and the roller head is extended, and the two end surfaces of the thrust face are rolled at the same time. When rolling, the rolling surface has good lubrication.NA500 type fine turning flange end face and groove machine tool is equipped with automatic detection device, after the parts are clamped, the probe automatically detects the distance from the thrust surface to the flange end face.The positioning accuracy of X-axis is 0.022mm, the repeatability of the positioning accuracy is 0.006mm, the positioning accuracy of Z-axis is 0.008mm, the repeatability of the positioning accuracy is 0.004mm.

GRINDMASTER crankshaft belt polishing machine is used to polish the oil seal neck, main shaft neck and connecting rod neck of the crankshaft. When polishing, the workpiece is firstly sprayed and cleaned, and then polished by using abrasive belts to wrap the parts. There are two rotating directions when polishing, and the final polishing direction is the same as the normal running direction of the engine (from the flywheel side); after polishing, the work is carried out for drying and degreasing, and the equipment needs to be equipped with its own polishing liquid treatment system.

Regarding HEGENSCHEIDT MFD7895 crankshaft rolling machine, the control system adopts Siemens PLC S7-300, the machine is installed with 9 rolling units, which are used to roll and straighten the crankshaft, the maximum rolling pressure is 30kN; pulse rolling of the connecting rod journals reduces the deformation of the workpiece; through the integration of pressure sensors and position sensors and rolling depth sensors in rolling units, the detection and monitoring of rolling pressure is realized; after rolling, the main journal runout is automatically detected and straightened by rolling; equipped with broken knife detection device; electronic measuring probe detects all main journals of the crankshaft radially. The pressure and position sensors integrated in the rolling unit and the rolling depth sensor enable the detection and monitoring of the rolling pressure; the main journal runout is automatically detected after rolling and straightened by rolling; a broken tool detection device is equipped; the radial runout of all main journals of the crankshaft is measured by electronic measuring probes; and the highest point of the connecting rod necks is detected by a laser head to identify the variety of the part.

HORKOS Imql crankshaft oilway hole and chamfering machine tool, the use of three steps on the oilway hole processing, milling plane → drilling oilway holes → chamfering, to overcome the original equipment a drilling step of unstable quality, frequent breakage of the knife and manual chamfering and other shortcomings of the equipment and the process capacity value of the one-time qualification, the cycle time is less than 1.3min.

COMAU SYME S10 Measuring and Calibrating Crankshaft Dynamic Balancing Machine consists of a measuring station, a pneumatic rotary transfer device, and a drilling calibration station; balancing measurement, measuring and displaying the amount of unevenness, automatic decomposition and calculation of the drilling data, drilling calibration, unevenness re-checking, and other actions are all automatic. The measurement uncertainty of the measuring station is ≤1g-cm, and the maximum drilling feed speed of the calibration station is ≥500mm/min.